May 27, 2024

OEM parts preserve the original quality and safety aspects of your vehicle. They perfectly fit in your car because the company that made it also designed them, preserving its structural integrity. However, aftermarket parts, although cheaper, may not suit your vehicle completely, causing potential risks to safety and performance. Trusting OEM parts for collision repairs simply means ensuring your own safety on the road. This will also help you maintain your car’s value in the long run.

Due to their perfect fit and functionality with your specific make and model, OEM parts are essential in collision repair. Using OEM parts ensures the highest quality, safety, and long-term performance for your vehicle, ultimately preserving its value and protecting its original specifications.

The Importance of OEM Parts in Collision Repair

Original equipment manufacturer (OEM) parts are like puzzle pieces designed by the vehicle’s original manufacturer to fit perfectly together. This ensures that every part functions in harmony with the others, maintaining the structural integrity and safety standards of your vehicle. When aftermarket components are used in collision repair , they may not fit as precisely as OEM parts, leading to potential safety compromises. Imagine putting together a puzzle where the pieces don’t quite match; it creates an unstable and unreliable structure. In the case of your vehicle, this could mean a compromised frame or an airbag that doesn’t deploy as intended in an accident. By sticking to OEM parts, you’re ensuring that every component fits seamlessly, guaranteeing maximum performance and safety.

It’s not just about ensuring safety; using OEM parts also plays a significant role in maintaining the value and integrity of your vehicle. While aftermarket parts can negatively impact the vehicle and exacerbate problems, OEM parts are engineered to meet high standards set by the manufacturer, providing reassurance that your vehicle will maintain its quality for years to come. Let’s look at it this way: You want to restore a historic building to its former glory. Instead of using original materials specifically designed for that structure, you opt for generic building materials because they’re cheaper. While this might seem cost-effective initially, it might compromise the building’s integrity and historical authenticity. The same principle applies when it comes to using OEM parts in collision repair.

OEM parts ensure efficiency and maximum performance without compromising vehicle safety. In the event of a collision, they are better protected thanks to their design, which adheres to strict safety standards set by the manufacturer. Utilizing OEM parts in collision repair ensures not only the quality and safety of your vehicle but also its long-term value and integrity. It’s a decision that prioritizes both immediate safety and a long-term investment in your vehicle’s well-being.

OEM vs. Aftermarket Parts: A Comparison

When repairing your vehicle after a collision, the parts you choose can significantly impact both the safety and overall performance of your car. OEM (original equipment manufacturer) parts are crafted by the same company that originally manufactured the components used in your vehicle, while aftermarket parts are produced by third-party companies as replacements for original parts.

One key difference between OEM and aftermarket parts lies in how they fit into your vehicle. OEM parts are specifically designed for your vehicle. The manufacturer extensively tests these parts to ensure they align perfectly with the rest of the vehicle’s components. This precise fitment can directly influence the safety and structural integrity of your car after repairs. On the other hand, aftermarket parts may not always offer the same level of precision in fitment. While some claim to be direct replacements, others may require modifications or adjustments during installation, potentially compromising your vehicle’s safety and long-term performance.

The quality and assurance that come with OEM parts cannot be overlooked. These components undergo rigorous testing and certification processes by the manufacturer, ensuring they meet strict quality standards and specifications. In contrast, the production of aftermarket parts may vary significantly in terms of materials used, construction methods, and adherence to industry standards. Another critical consideration when comparing OEM and aftermarket parts is their impact on warranty coverage. Utilizing OEM parts for repairs frequently ensures that you keep the original manufacturer’s warranty, offering additional security and assurance from the car’s creator.

While aftermarket parts may offer cost savings upfront, it’s essential for vehicle owners to carefully weigh these short-term benefits against potential compromises in fitment, quality, safety, and warranty coverage when making decisions about collision repair.

Certifications and Warranties with OEM Parts

When your car gets damaged in an accident, ensuring high-quality repair work is paramount. By using OEM (original equipment manufacturer) parts, you are already setting a standard for quality. These parts are specifically designed for the make and model of your vehicle, ensuring a perfect fit and optimal functionality.

Notably, many OEM parts come with warranties from the manufacturer, guaranteeing quality and performance. This warranty acts as a promise to the consumer that if the part is found to be defective due to materials or workmanship, the manufacturer will step in to repair or replace it at no extra cost. This level of assurance not only provides peace of mind but also reflects the manufacturer’s confidence in their product.

Equally important is how using OEM parts helps maintain the original vehicle warranty, acting as a guarantee from the automaker to repair or replace any damage from defective materials or workmanship. However, using non-OEM parts in repairs can potentially void this factory warranty and lead to potential conflicts with the manufacturer’s warranty terms. By sticking to OEM parts for repairs, you ensure that your vehicle remains within the boundaries of its original warranty coverage. This means that if there are any issues related to the specific part affected by the accident, it’s likely still covered by the original factory warranty, whereas using aftermarket parts could potentially void certain aspects of this warranty.

Another aspect of using OEM parts for collision repairs is certification. It’s crucial to ensure that both the parts and the repair shop meet certain quality standards. Many automakers provide certification programs or partnerships with specific repair shops to ensure that their vehicles are properly handled after an accident. By choosing a certified auto body repair shop, like Ken Rocha Collision, you have greater confidence that they are using genuine OEM parts and following proper repair procedures specified by the manufacturer. These shops have demonstrated their ability to meet strict standards for training, equipment, and customer service, giving you added peace of mind regarding the quality and reliability of the repairs being done on your vehicle.

Potential Cost Implications of OEM Parts

OEM parts are indeed associated with higher upfront costs compared to aftermarket components, which might make you contemplate the cheaper options. However, despite the initial cost being higher, OEM parts can ultimately save you money in the long run. How so? Let’s break it down: OEM parts are made to fit your vehicle perfectly, just like the original ones that came with it when you first bought it. This precise fit reduces the chance of issues cropping up later on. With aftermarket parts, there is a risk of misalignment or an imperfect fit, potentially leading to additional repairs or replacements down the line.

Moreover, the quality and durability of OEM parts often mean that they outlast aftermarket components. A part that lasts longer means fewer replacements and fewer frequent visits to the mechanic; this can add up to substantial savings in the long term. For instance, let’s take a look at a critical component like the airbags. The safety and reliability of OEM airbags are crucial because they have been specifically designed to work with your vehicle’s safety system. Investing in these high-quality OEM airbags can directly contribute to your safety in an accident. In comparison, an aftermarket airbag might not fit perfectly or function as effectively, potentially jeopardizing your safety in a collision.

Additionally, choosing OEM parts can safeguard your warranty by ensuring that the manufacturer will cover repairs. It’s not just about longevity. This added protection is something you don’t always get with aftermarket parts. Ultimately, while aftermarket parts may seem like the more budget-friendly option initially, their potential for premature wear and reduced safety standards can make them more costly in the long run. When weighing the costs of OEM versus aftermarket parts, it’s important to consider the long-term benefits of investing in superior quality and lasting performance. After all, quality isn’t expensive; it’s priceless.

Impact of OEM Parts on Vehicle Performance

When a vehicle is involved in a collision, it’s not just the visible exterior damage that needs attention. There can be intricate components and systems inside the vehicle that also need to be assessed and potentially repaired or replaced. This is where the importance of using OEM parts becomes evident. OEM parts are crucial in getting the car back to its pre-accident state and ensuring that it runs as the manufacturer intended. Imagine a finely tuned machine, each part designed to work seamlessly with the others. When one piece is altered or replaced with something subpar, it can disrupt the entire system. That’s why aftermarket components are not recommended for collision repair; they may not meet the same high standards as OEM parts and can compromise the performance and safety of the vehicle.

Fuel efficiency, handling, and the overall driving experience are all influenced by the quality and fit of the components used in repairs. When OEM parts are utilized, they ensure that the vehicle operates at its optimum level. These parts are engineered specifically for the make and model of the vehicle, guaranteeing that they seamlessly integrate with other systems to uphold efficient performance. For instance, an OEM bumper or headlight assembly bracket is designed to fit perfectly onto your car’s frame, maintaining its aerodynamics and protecting crucial internal components. This precise fit wouldn’t be guaranteed with aftermarket parts, potentially leading to less efficient airflow around the vehicle.

With these significant implications in mind, it becomes clear that when it comes to collision repair and restoring a vehicle’s performance post-accident, opting for OEM parts is a prudent choice that preserves both the mechanical integrity and driving experience of your vehicle.

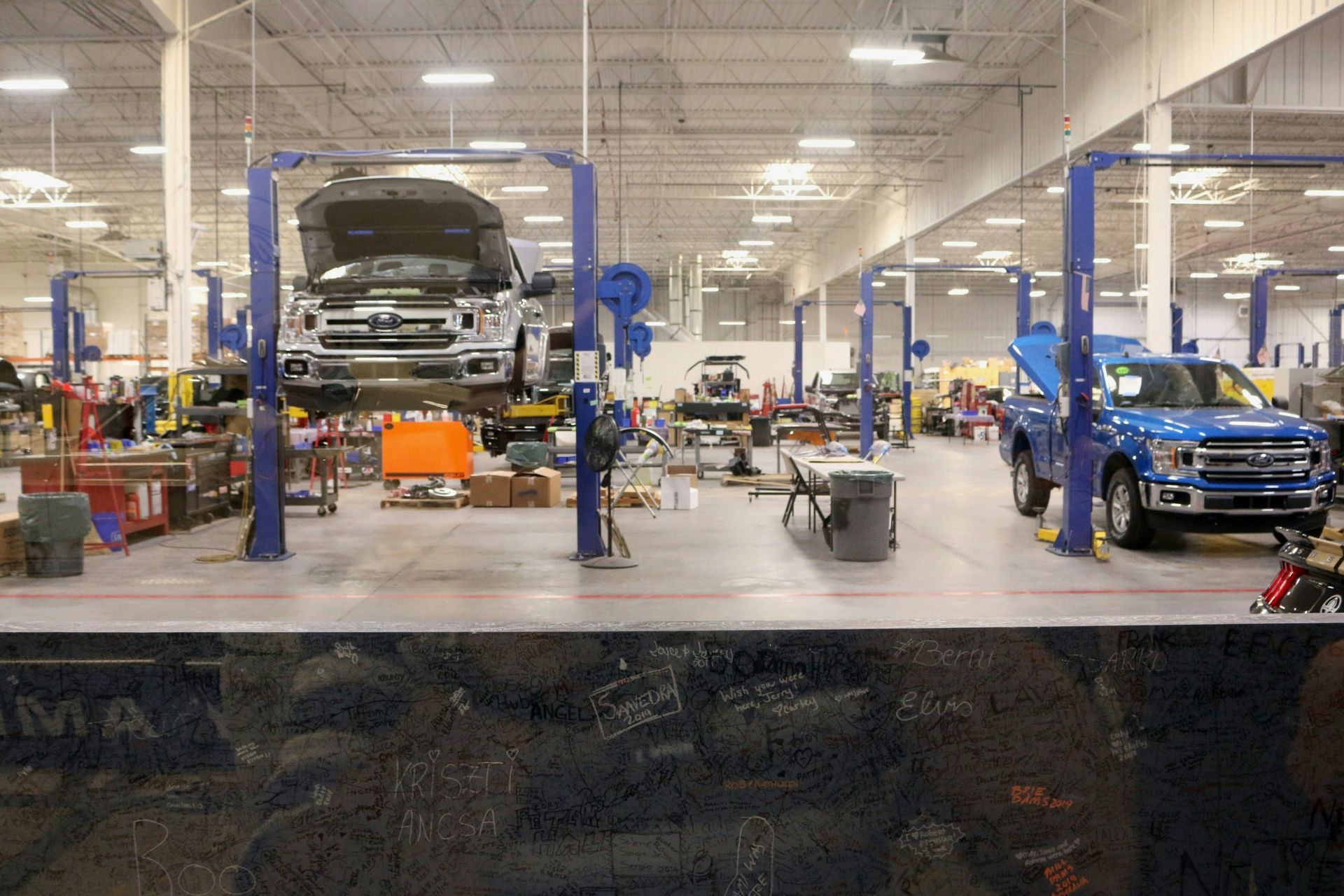

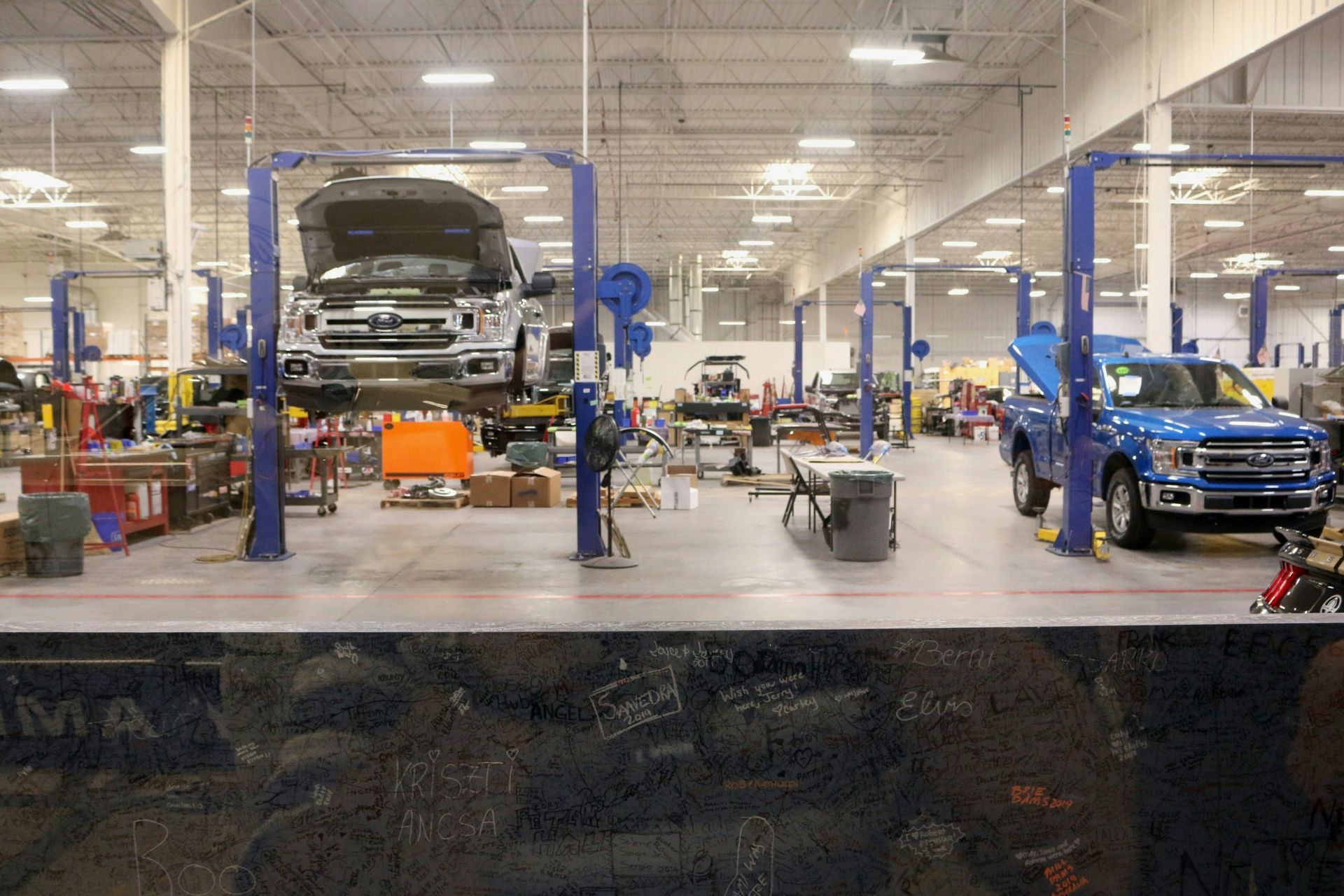

Leading Collision Repair Services Provider in Providence, RI

In need of top-tier collision repair services in Providence, RI? Look no further than Ken Rocha Collision. With a reputation for excellence and a commitment to customer satisfaction, Ken Rocha Collision stands as the leading provider of collision repair in the area. From minor dents to major collision damage, our skilled technicians utilize state-of-the-art equipment and techniques to restore your vehicle to its pre-accident condition. We use OEM (original equipment manufacturer) parts and ensure that every repair meets the highest industry standards for quality and safety.

At Ken Rocha Collision, we understand the stress and inconvenience that come with auto accidents, which is why we strive to make the repair process as seamless as possible for our customers. Don’t settle for anything less than the best when it comes to repairing your vehicle; trust our experts to get the job done right. Schedule your appointment today and experience the unmatched quality and service that set them apart from the rest!

The post The Importance of OEM Parts in Collision Repair appeared first on Ken Rocha Collision.